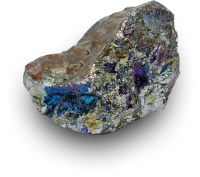

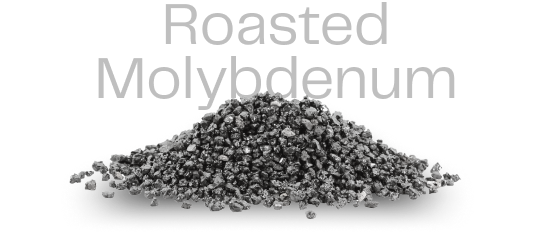

Roasted Molybdenum

Molybdenum has a very high melting point so it is produced and sold as a grey powder. Many molybdenum items are formed by compressing the powder at a very high pressure.

Roasted Molybdenum concentrate also known as Technical Molybdenum Oxide is Mo containing intermediary product being produced by roasting at air temperatures of Molybdenum Disulphide (MoS2) concentrate (typical MoS2 content 85-92%, S ab. 35-37%). The resulting roasted Mo concentrate typically contains minimum ab. 57% molybdenum, and less than 0.1% S. Between 30-40% of Global Technical Mo Oxide production is processed into Ferromolybdenum and ab. 25-30% into different chemical products (Chemically pure Molybdic Oxides and Molybdates).

Significant part of Technical Molybdenum Oxide is also used for direct alloying of steel with Molybdenum in EAF and Converter type furnaces (to achieve Mo content in EAF furnaces up to 3% and up to 1% in Converter-type furnaces). Compared with Ferromolybdenum, Technical Molybdenum oxide preferences are lower cost and quicker dissolution rate.

Compared with Ferromolybdenum, Technical Molybdenum oxide preferences are lower cost and quicker dissolution rate.

Download product specifications

Download product specifications